Digital transformation is a process of "evolution" of enterprises, not just technical problems. Transformation involves all aspects of enterprises. Enterprises should keep pace with technology and management, promote the reform and innovation of enterprise management on the basis of clarifying digital strategy and direction, and finally realize digital transformation and achieve smart enterprises. Nowadays, with the rapid development of digitization, enterprises gradually take information and knowledge management as their core competitiveness. The digital transformation of engineering construction enterprises is the inevitable trend of the development of the times. In the construction process of the project, the project management system is designed through digital technology to control the high-quality delivery of the project and generate their own data assets. This paper analyzes the application scenario of BIM Technology in the management system from the complete construction of digital infrastructure, carries out the design of management system of engineering projects, and serves as a reference for the design scheme of management system for enterprise digital transformation.

The essence of digital economy lies in informatization. The infrastructure of informatization is very important. There are many technologies related to it, including sensing terminal, 5g network, optical fiber broadband, big data center, industrial Internet, etc., as well as the use of new generation information technologies such as Internet of things, edge computing and artificial intelligence. The development of these technologies has to give birth to changes in enterprises. Since it was officially connected to the Internet in 1994, China has entered the Internet era, with increasingly sound information infrastructure and gradually improved information infrastructure. In 2017, the report of the 19th CPC National Congress fully affirmed the far-reaching impact of digital economy on the optimization of economic structure in China's economic construction, and the digital economy has gradually risen to the height of national strategy. In 2021, the outline adopted by the two sessions mentioned "accelerating digital development and building a digital China". Digital economy has become an important driving force for China's economic transformation and upgrading and the commanding height of a new round of global industrial competition. In today's increasingly day-to-day competition, traditional enterprises need to obtain the ability of sustainable development through management reform and technological innovation. Enterprises can accelerate the transformation of internal management and business management with the help of digital innovation.

1、 Digital infrastructure construction

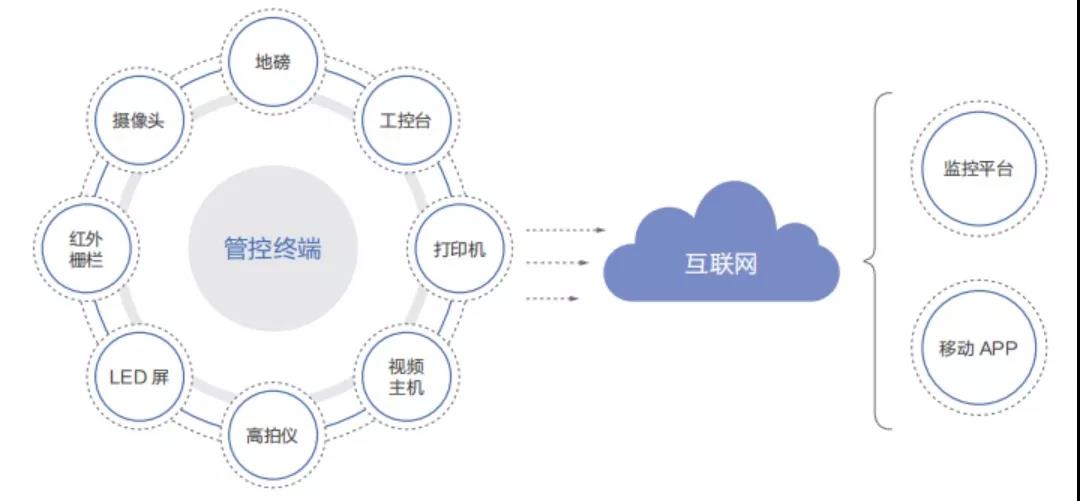

To accelerate the transformation of enterprise internal management and business management, the construction of digital infrastructure is particularly important. It is not only the basis of enterprise digital transformation, but also the necessary condition for the success of enterprise transformation. Of course, the situation of different enterprises is different. The development of enterprises should start from their own actual situation, do not digitize for the sake of digitization, and clarify their strategic positioning step by step. Combined with the development and progress of new technologies in the times, in April 2020, the national development and Reform Commission defined the scope of "new infrastructure" for the first time, and digital construction has been promoted in many industries. Nowadays, BIM Technology has been widely used in China's infrastructure projects, such as road and bridge construction, railway construction, port construction, municipal engineering, etc. BIM collaboration platform and management platform have been built to realize the efficient collaboration of design data and models of various disciplines, participants and stages.

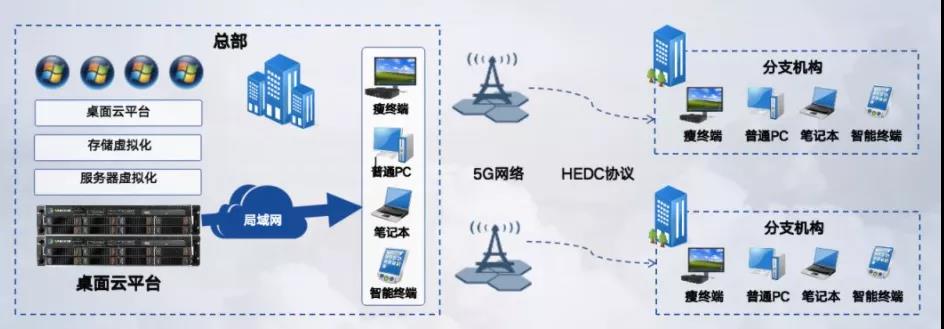

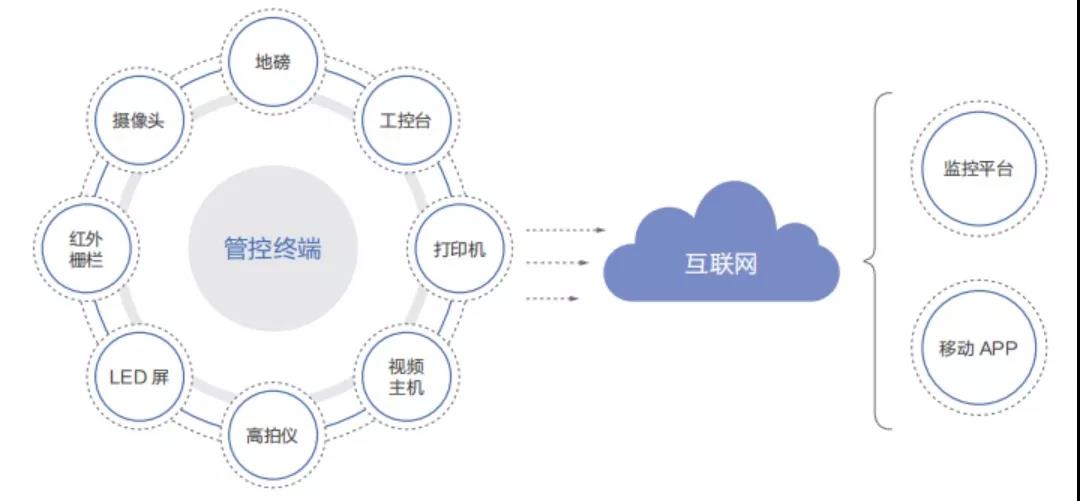

Now, large central enterprises, state-owned enterprises and private enterprises are exploring the practice of digital transformation, and have also made some achievements and played a leading role. The problem of information island and the integration of industry and finance, which have puzzled enterprises for many years, can realize the whole network connection through the establishment of enterprise information infrastructure (Enterprise Cloud), so as to solve the practical problems in the digital world. For example, when CCCC was designing and reconstructing Shenzhen Meiguan expressway, it applied the UAV tilt photogrammetry real scene technology in large scene and complex environment to the design, realizing the innovation of design basic data and design method; China Railway constructs a procurement e-commerce platform to realize the standardization, standardization, intensification and informatization of procurement management, and form sunshine procurement with multiple parties into a commercial ecological chain. Information infrastructure construction includes hardware facilities construction, software facilities construction, performance guarantee construction of software and hardware systems, etc. information infrastructure construction is shown in Figure 1.

Figure 1 | information infrastructure construction

(1) Definition of digital infrastructure construction by enterprises

Enterprises of different sizes should carry out digital development in combination with their own situation. For traditional enterprises, after years of development, they have their own core products. Most of the time, information technology is the support of enterprises. The information technology of small enterprises is mainly used in the system carrying business. Therefore, compared with digital infrastructure, they pay more attention to the transformation of business system. For example, they can obtain a business system more suitable for production and management characteristics at a lower cost, or get through marketing and customer service. These transformations are of great practical significance.

With regard to the construction of digital infrastructure, there is a view of "soft before hard". In the past, most enterprises used to the development mode of hardware investment first. Once this development mode is determined, it is difficult to dynamically adapt and flexibly adjust. If the planning is wrong, it is easy to cause a waste of resources. Especially when the data is not connected, more hardware investment may cause more information non circulation and mismatch, forming more data islands. Therefore, based on the existing hardware infrastructure, it is a more scientific and reasonable circular construction mode to get through the data through software. For medium-sized or large-scale traditional enterprises, the problems of many business segments, numerous systems and heterogeneous and decentralized basic resources are easy to form a bottleneck affecting the digital development of enterprises. If leaders assign a task of "business connection" or "fast online", it will be difficult to implement the task without platform digital infrastructure.

(2) Hardware facilities construction

Enterprises need appropriate hardware to support digital work, including BIM model creation, digital management and other requirements. Unqualified hardware will reduce work efficiency and even lead to task failure. Purchasing and arranging according to strategic positioning is conducive to enterprise digital management.

1. Network infrastructure construction

The construction of network facilities is to use network communication technology to establish a wide relationship between enterprises and people, people and things, things and things, and realize the full connection between internal and external. Firstly, using broadband communication technology and Internet of things technology, build an enterprise private network within the scope of enterprise activity space to form the core of enterprise network infrastructure; Secondly, with the help of public mobile network communication technology and Internet of things technology, build a virtual private network within the enterprise activity space and form a supplement to the enterprise network infrastructure; Moreover, access to public broadband and mobile communication networks, build channels between enterprises and external connections, and realize the opening of enterprise network infrastructure; Finally, while realizing network interoperability, do a good job in network security construction and improve the enterprise's own network security management.

Establish a network center system with full coverage of LAN, Ethernet and unlimited network, including power distribution system, generic cabling system, fire protection system, air conditioning system, network system, etc. Introduce hardware equipment, including core switches, firewalls, servers, data storage and other hardware infrastructure, and build a complete information infrastructure hardware platform. For communication and transmission, Internet access optical fiber private network and video monitoring lines are built, which are integrated and managed by the platform to realize the special line connection with each office area. At the same time, pay attention to building a network security guarantee system to ensure the safe, stable and reliable operation of digital infrastructure.

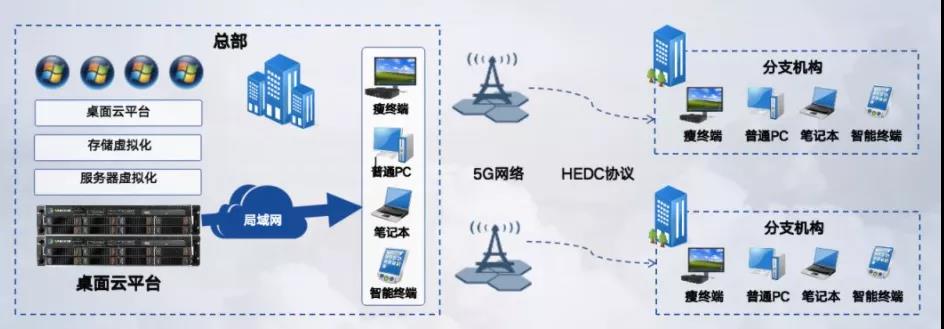

2. Cloud platform infrastructure construction

In terms of infrastructure construction, the cloud platform includes cloud operating system, distributed file system, cloud service center, distributed service bus, load balancing and other key components. Cloud infrastructure construction is to use cloud technology and edge cloud technology to establish enterprise cloud resource pool and cloud platform architecture to realize enterprise cloud operation. For enterprises that have conditions and pay special attention to security, cloud technology and edge cloud technology can be used to build a cloud resource pool independently developed by enterprises and promote the cloud deployment of various platforms of enterprises; For general enterprises, build the exclusive cloud needed by enterprises with the help of cloud resource pool and Cloud Architecture of cloud public service enterprises.

(3) Software facility construction

According to the above establishment of cloud platform infrastructure, cloud opening capacity construction is proposed. Cloud opening capacity building is to use software, virtualization and other IT technologies to establish enterprise capability encapsulation and cloud, so as to realize the opening of capabilities to the inside and the outside world. First, virtualization, software definition, standardization, capability encapsulation and cloud deployment are carried out for the human, financial and other resources that enterprises need to share internally and open to the outside world, so as to form an open capability; Second, refine, standardize, encapsulate and cloud deploy mature businesses or services that need to be developed on a universal scale.

According to the overall strategic planning needs, drive value and value driven practice, and deploy digital infrastructure according to enterprise development. OA integrated management system, information management system (LIMS), online monitoring system, backup resource management decision system, IVMs integrated security management system and various application subsystems within the enterprise, and integrate various existing system software to establish the engineering big data platform. Realize the effective collection, rapid transmission and information sharing of business information such as project supervision, inspection and testing, achievement management and administrative office.

(4) Performance guarantee of software and hardware system

The maintenance of digital infrastructure requires human and material resources to ensure the performance of software and hardware facilities. In this regard, the normal operation of software and hardware can be ensured through monitoring, diagnosis, implementation and change, design and optimization. Through the online behavior policy management tool, network managers can carry out network security management, and define, allocate, execute policies and check security status through the browser graphical interface. In terms of software reliability, security and ease of use, the genuine office software shall be purchased uniformly to ensure the consistency of the software. In addition, various information systems strive to provide convenience for employees' operation with simple operation, perfect function and humanized interface. While strengthening the software and hardware infrastructure, formulate relevant specification documents to improve the reliability, security and ease of use of software and hardware, and ensure that the information system infrastructure meets the needs of enterprise strategic development.

2、 Design of engineering digital management system

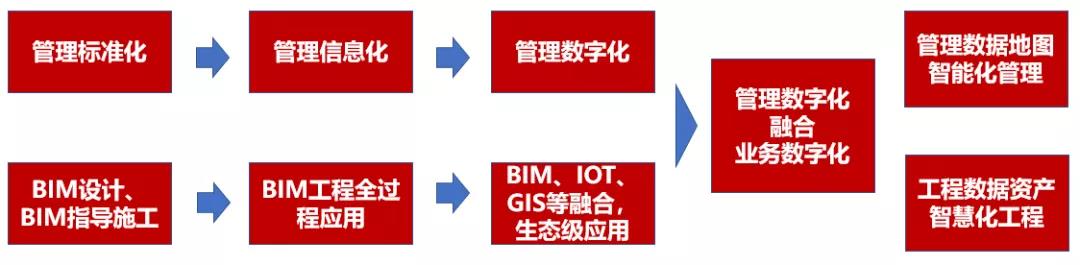

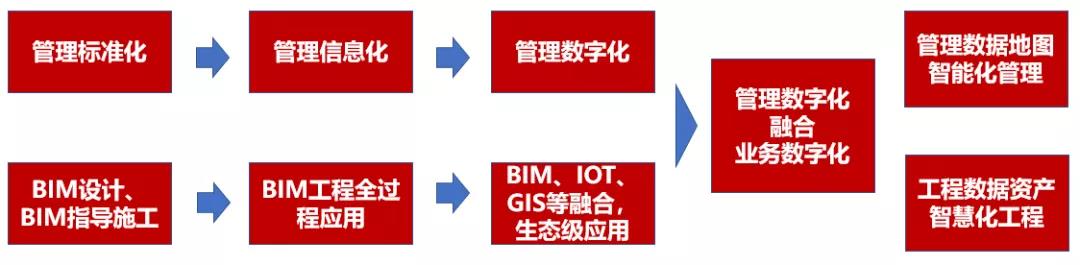

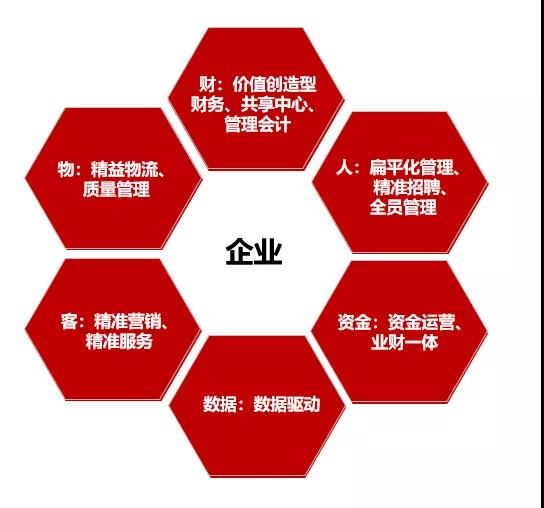

The establishment and improvement of digital infrastructure is conducive to the implementation and management of the project. In the process of digital management, the engineering digital management system can be distinguished: management digitization and business digitization. Management digitization is divided into decision management, simulation management and personnel management; Business digitization is the management of engineering project construction process. Standardization is the basis and premise of enterprise management digitization. Standardization is not only the standardization of system, but also includes the standardization of technology, organization, product specialization, as well as specific management and human resources. The path of enterprise management digitization and business digitization is shown in Figure 2.

Figure 2 | path of management digitization and business digitization

(1) Digitalization of enterprise management

The digitization of management, in general, is informatization. It focuses on the management of our enterprise and realizes the internal management and operation of the enterprise through the information system. With the change of management concept and technology, the process of digitization of management has changed from ISO9000 and three standard system in the past to the standardization of enterprises, then to informatization, and to the digitization of management in the future.

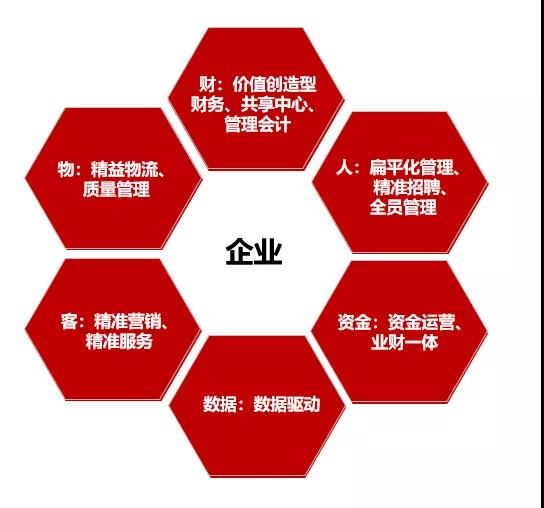

1. Management around enterprises

The internal information management of an enterprise includes OA comprehensive administrative system, financial system, superior and subordinate group management system, etc., which is the basis of digital management, as shown in Figure 3 below. On the basis of enterprise information management, the internal information management and business operation management of the enterprise are integrated on the information system, and the information system of the whole enterprise is formed into a network to form a data platform and a database. Of course, with some successful domestic enterprises with strong economic and technological strength, they have achieved a certain integration on this basis.

Figure 3 | enterprise internal information management field

2. Upload real-time data for decision management

In the process of project operation, decision-making, as an important management link, occupies a major position in the management process. During the operation of the project, upload the real-time database in time, use big data, artificial intelligence and other technologies, fully analyze the geographical environment, transportation status and project construction progress, and make effective decisions, so as to promote the accuracy and intelligence of decision analysis. The database uploads the real-time data of the construction project to the decision-making management part to help the decision-making management part make decisions according to the real-time data of the construction project. At the same time, the decision-making management part will input relevant data requirements to facilitate the data module to collect and sort out effective data. Integrate the perfect data information into a digital model, realize the digital management of construction engineering enterprises, and improve the timeliness and quality of construction engineering management.

3. Simulation management using computer technology

Carry out specific collection of construction project data information. After completing the data collection, input the data into the project plan and model construction, carry out specific numerical calculation, and then simulate the results. The data management of the simulation module is mainly to completely build the construction model, and input the actual data of project construction in the process of project construction, The ideal value is used to analyze the real value, and the data model is visualized and visualized to help the decision-makers better understand the overall situation of the current project and formulate a scientific and reasonable scheme. The decision-making function is shown in Figure 4.

Figure 4 | intelligent decision-making

4. Personnel management

As far as most enterprises are concerned, the personnel composition has the characteristics of diversity and variability. In the traditional management mode, due to the large demand for construction personnel and more posts, personnel arrangement and management activities are complex, and managers can not carry out comprehensive and effective management activities. Use computer information means to bring personnel management activities into the management module, fully understand the personnel arrangement status by means of information means, and improve the efficiency and accuracy of personnel management activities. In the process of personnel management, attention should be paid to fully mastering the specific data of employees, so the establishment of employee information module is very important. Secondly, the salary status of employees is a part that enterprises and employees attach great importance to. In the process of establishing the salary module, the salary composition form needs to be completely established. The department division module is direct for the personnel management of construction projects. The construction of department management module is conducive to the clear division of personal responsibility.

(2) Business digitization

The specific construction of project construction module is directly related to the construction process of the project. In order to complete effective management, it is necessary to establish systems for the five parts of the project: construction progress, quality, capital, contract and materials, and input real-time data for each part.

1. Operation progress

Construction progress is particularly important in various management of construction engineering. Doing well in construction progress management can effectively ensure the smooth progress of construction. During the management of construction progress, the engineering team needs to formulate a reasonable project construction plan according to the project construction requirements and design drawings. In the actual operation process, the construction management personnel need to record the daily project status and upload the specific data in real time, so as to see the real and accurate data in the construction management process.

2. Project quality inspection

In the process of project quality management, it is necessary to formulate a strict inspection catalogue of project quality index system according to the quality requirements of the project. In the process of project quality inspection, it is necessary to customize the correlation detection tools according to the detection requirements. After the detection, it is necessary to input the inspection data into the project quality management system for data analysis. For the data with large differences, it is necessary to compare the quality management data and detection methods to finally find out the reasons for the quality differences, And adjust the construction mode. In the process of establishing project quality data management, it is first necessary to complete the calculation of quality data according to the project framework and project quality requirements, and input the specific data into the system. In the later process of quality inspection, it is only necessary to input the actual data to complete the calculation of quality eligibility.

3. Material management

Materials are the basis for the normalization of construction of the project, and the total cost of materials accounts for about 50% of the total investment of the project, while bulk materials account for about 70% of the total cost of materials. This fully reflects the importance of material management in the project construction process, and ensuring sufficient materials is a necessary condition for project implementation. The implementation of material management is mainly divided into three parts: Planning (formulation of material demand and quantity), purchase and warehousing (in and out of the warehouse). That is, before the project construction, calculate the required materials and determine the quantity of materials required for construction, which is conducive to the management department to directly monitor and manage the calculation rationality of materials. After the material demand module completes the accounting, the purchase module purchases materials completely according to the material demand data. After the purchase module is completed, since the material application is a long-term process, the work of the material storage module is important. In the process of material management, it is necessary to make strict statistics on the incoming and outgoing materials, In order to fully manage the application of materials. Data management is carried out from the planning, procurement and storage of materials to visualize the physical objects and data, so as to achieve the best state of material management (Fig. 5).

Figure 5 | digital material management

4. Project fund management

In the process of construction, it is necessary to calculate the project construction funds reasonably, that is, the project cost. After the fund accounting is completed, the budget needs to be submitted for approval. The management department reviews the fund plan according to the approval department, and systematically enters the specific fund application. The fund use of each link in the project construction process needs to be input, and the fund application of each link in the project construction process will be effectively managed, In case of insufficient funds, the comparison can be made according to the fund plan and the actual use of funds, so as to complete the effectiveness management of funds. Build a sharing platform to realize intensive management of people, finance and materials.

5. Contract management during construction

The construction process has the characteristics of long-term and complexity. In the process of construction project development, there will be a clear contract signing in the early planning, bidding and bidding process. The responsibilities of the construction party and the management party in the contract content are clear. At the same time, in the later project construction process, the supply of materials The responsibility differentiation of the construction team requires specific constraints of the contract. Therefore, the contract is of great importance in the whole process of project construction. In the process of contract management, it is necessary to upload the contract signed at each stage to the system, and conduct specific screening and management of the regulations such as responsibility and breach of contract, so that in case of disputes in the later management process, the responsibility can be attributed according to the contents agreed in the contract.

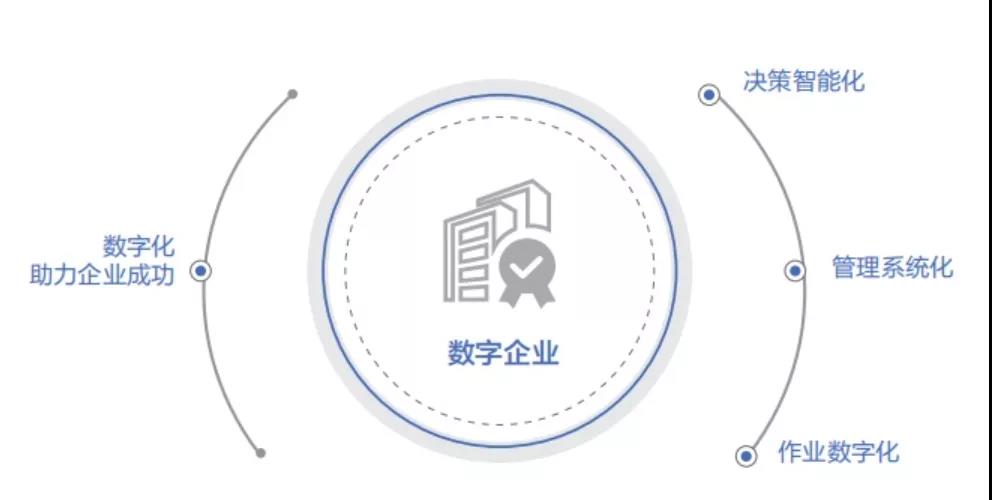

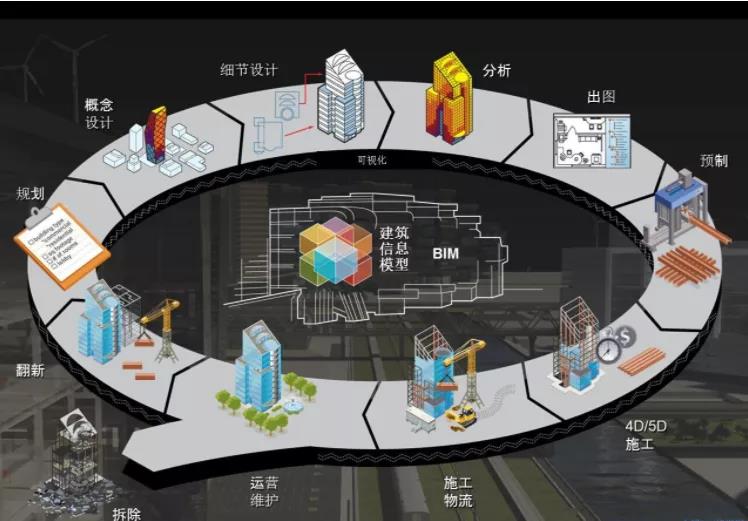

3、 Application analysis of Engineering Management Design

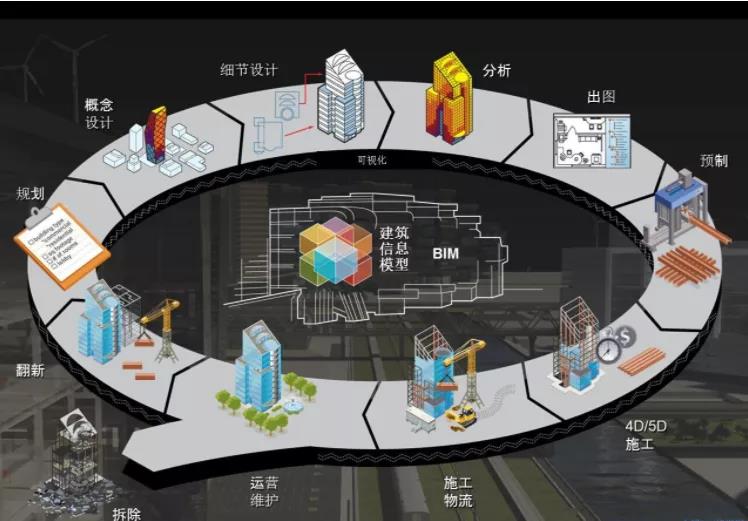

Digital technology represented by parametric design and building information model provides a new driving force for design innovation in the construction industry. In building construction, with the support of digital technology, building design, part processing, on-site construction and other links can be deeply combined to accurately control the accuracy and quality of construction and improve the quality of completed works. The digitization of engineering construction industry is represented by the development and application of BIM Technology. It can transform the traditional two-dimensional drawing design into a dynamic and complete three-dimensional model, present complete information and engineering model to all project participants, facilitate the discovery and solution of problems before construction, reduce the errors of on-site assembly components, reduce the waste of materials, and shorten the construction period Improve construction efficiency, improve project quality and facilitate later maintenance. From the establishment of infrastructure to the management of engineering projects, the main BIM Technology can be applied, as shown in Figure 6. The integration and innovation of landing BIM Technology and engineering construction achieve the integration of design and construction, open up the scheme layer, application layer and platform layer, and make more intelligent applications form an intelligent network based on "BIM + big data + cloud computing", so as to realize horizontal, vertical and end-to-end high-level integration.

Figure 6 | BIM collaboration platform

As the data carrier of the whole life cycle of the building, BIM model provides a unified data exchange mode in the process of information integration at each stage of the project, which is conducive to the sharing of project information. For the future operation stage, BIM can ensure that the data input in the early stage can be used by facility management professionals continuously, eliminating the time of data integration or collection in the past, Directly improve the reuse rate of data and reduce the possibility of human cost and human error in the operation stage. The setting of BIM building information model data management is shown in Figure 7 below.

Figure 7 | setting of BIM technical information model data management

At present, the main typical application scenarios of digital technology in engineering construction industry are:

(1) Information integration

At present, the "distributed" BIM model is mainly used in China. In more and more projects, the owner will establish a unified platform or entrust a consulting company with mature technology to build the platform. This platform has a unified data format and is compatible with the familiar data forms of all parties to the greatest extent. In addition, the design institute and the construction unit will also use this model maintenance platform and technology for internal management.

(2) Site analysis

Through the combination of BIM Technology and GIS (Geographic Information System) technology, the accuracy of site analysis is greatly improved. In the early planning stage, BIM can obtain the information in GIS through data exchange and accurately evaluate the use conditions and characteristics of the site, so as to make the most ideal site planning, traffic streamline organization relationship, building layout and other key decisions for the new project. In recent years, with the national and local governments vigorously promoting the construction of sponge city and underground pipe gallery, the combination of Bim and GIS becomes more and more important.

(3) Planning and demonstration

BIM can help the project team understand the standards and regulations of complex space through the analysis of space and building functions in the building planning stage, and help make decisions when analyzing needs and schemes. With the selection of each scheme, through the linkage of data, provide the investor with the cost estimation of the corresponding scheme, and help the investor achieve selection and decision-making.

(4) Visualization

Compared with the traditional visual design, the visual design using BIM Technology has stronger authenticity. Moreover, each stage of design deepening and change can quickly generate renderings and roaming animation. Not only for early communication with investors, visualization also has many uses in the process of project implementation. BIM Technology enables the communication, discussion and decision-making in the process of project design, construction and operation to be carried out in a visual state.

(5) Collaborative design

Collaborative design refers to the design work carried out by different professional designers distributed in different geographical locations through the network. The traditional cooperation mode is fragmented. Drawings, design specification documents, material lists, changes, etc. are transmitted to each other in a discrete state. Each file is independent and cannot be associated with other files. The bottom logic of BIM prevents the independent change of information, and the transmission mode of information among collaborators has also changed. All parties can participate in the cooperation and change in real time.

(6) Performance analysis

In the process of creating digital building model, it already contains a lot of information, such as geometric information, material properties, component properties and so on. Through special analysis software, performance analysis can be carried out, such as lighting, energy consumption, air organization and so on. Compared with the past, it greatly reduces the cycle of performance analysis, improves the design quality, and enables the design company to provide more professional skills and services for the owner.

(7) Quantity statistics

BIM model is a database rich in engineering information, which can truly provide the quantities information required for cost management. With the help of this information, the computer can quickly make statistical analysis of various components, greatly reducing manual operation and potential errors. It can be used for the cost estimation in the preliminary design process, as well as the quantity budget before construction and the final settlement of quantities after construction.

(8) Collision inspection and pipeline integration

Through the information provided by the BIM model and the collision detection program, the collision inspection report can be automatically generated, and then corrected by the designer, so as to solve the potential collision problems before the formal construction. This is also the main application point for most enterprises or projects to promote and apply BIM Technology.

(9) Simulation and management of construction progress

Construction is a highly dynamic process. With the continuous expansion of the scale and complexity of construction projects, construction project management becomes more and more complex. The traditional project management mainly uses grid chart and bar chart to represent the schedule. And it mainly depends on the experience of project managers, with low accuracy. 4D schedule simulation can intuitively show the whole construction process and provide a visual platform for project managers. The resource allocation information of all people, materials and machines is consistent with the construction progress in the model. Project managers can intuitively see the current construction progress and timely find and adjust the problems in the construction process. It can also be used to evaluate the main construction control methods, construction arrangements and overall plans of the bidder in the bid evaluation stage to make effective decisions.

(10) Construction site planning

The BIM model can be used for scientific three-dimensional planning of the construction site, including the layout of workers' living area, material processing area, material warehouse, on-site material stacking site and on-site roads, as well as the route planning of construction machinery and vehicles. Visually reflect the on-site construction situation, effectively use the construction land, ensure the smooth on-site transportation road, facilitate the management of construction personnel, and avoid secondary handling and accidents.

(11) Key and difficult construction simulation disclosure

Using high-precision BIM model and time axis, we can make animation of construction process for on-site construction personnel, add text description and sectional drawing inside components at key nodes, and even carry out interactive construction guidance. In the process of making construction guidance, problems in the installation process can also be found as soon as possible and solved before construction.

(12) Digital manufacturing

BIM combined with digital manufacturing can improve the production efficiency of the construction industry and realize the automation of construction process. Many building components can be processed in different places and transported to the site for assembly. Through BIM model, the accurate size and processing drawing of component model can be derived after collision inspection and installation simulation, so as to reduce the error, better realize the prefabrication of components, greatly improve the production efficiency, shorten the construction period and be easy to control.

(13) Material tracking

With the improvement of standardization and digitization in the construction industry and the complexity of construction equipment, more and more building and equipment components can be prefabricated and transported to the site for assembly. BIM software can record the necessary information of components in the modeling process, such as production date, manufacturer, size, number, telephone, maintenance records, ID coding and generate bar code or QR code, which is conducive to the smooth implementation of construction plan.

In terms of business digitization, most enterprises are still in the stage of BIM design and BIM construction. In the future, they need to develop to smart engineering and smart city, integrate and apply with IOT, GIS and other technologies, and realize the digital management of enterprises.

4、 Conclusion

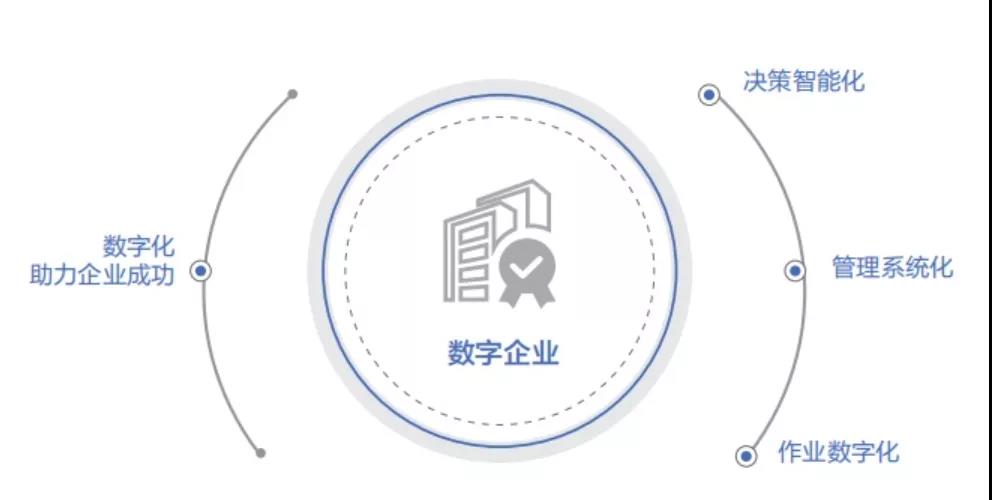

Realizing the integration of digital management and digital business is the future goal, that is, the information system should directly capture data from the data model at the project level. In the future, a data map for management will be formed in terms of management to realize intelligent management. In terms of engineering, there are engineering digital maps, engineering digital assets and big data to realize the intelligence of engineering. Under the background of digital transformation, based on digital infrastructure construction, this paper analyzes the design of engineering construction project management platform architecture, and details the application of BIM Technology in engineering management, hoping to have some reference significance for the digital transformation of engineering construction enterprises.

Return list

Return list